Abstract

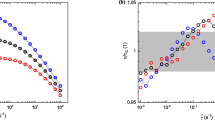

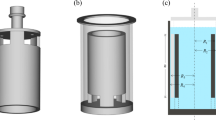

Neglect of end effects in Couette rotational viscometry introduces a 10–30% error in the estimate of shear stress at the spindle surface. Actual deviations depend on the shear-thinning level of a given sample. We tackle the end effect for the standard sensor Z40 DIN according to the ISO 3219 by solving the related 2D boundary-value problem for a class of shear-thinning viscosity functions. The pseudosimilarity method of treating the primary data leaves an error of about 0.5% in shear stresses. Further reduction in the errors needs a full numerical simulation for each point of the primary data based on a suitable wide-range representation of the viscosity function. To support a high accuracy of torque calibrations, the effect of inertia on torque for Newtonian liquids in standard sensor Z40 DIN at Re < 500 is calculated using the FLUENT 6.2 commercial software.

Similar content being viewed by others

References

Ancey C (2005) Solving the Couette inverse problem by using a wavelet-vaguelette decomposition. J Rheol 49:441–460

Astarita G (1990) The engineering reality of yield stress. J Rheol 34:275–277

Barnes HA (2000) A handbook of elementary rheology. University of Wales, Aberystwyth, UK

Barnes HA, Walters K (1985) The yield stress myth? Rheol Acta 24:323–326

Code RK, Raal JD (1973) Rates of shear in coaxial cylinder viscometers. Rheol Acta 12:578–587

ISO 3219 (1994) Determination of viscosity using a rotational viscometer with defined shear rate (Plastics-polymer/Resins in the liquid state or as emulsions or dispersions). CEN, Brussels, Belgium (See also DIN 53 019)

Krieger IM, Elrod H (1953) Direct determination of the flow curves of non-Newtonian fluids. II. Shearing rate in the concentric cylinder viscometer. J Appl Phys 24:134–136

Mooney M (1931) Explicit formulas for slip and fluidity. J Rheol 2:210–222

Nguyen QD, Boger DV (1992) Measuring the flow properties of yield stress fluids. Annu Rev Fluid Mech 24:47–88

Paddon DJ, Walters K (1979) On edge effects and related sources of error in rotational rheometry. Rheol Acta 18:565–575. DOI 10.1007/BF01520352

Roscoe R (1962) The end correction for rotation viscometers. Br J Appl Phys 13:362–366

Uby L, Hallgren G, Fahlgren M, Svensson T (2006) Searle and Couette rheometry: correction for arbitrary gap size and end effect of non-Newtonian fluids. In: 3rd Annual Rheology Conference, AERC 2006, Crete, Greece, 27–29 April 2006

Wein O (1976) The non-Newtonian creeping flow around a rotating spheroidal spindle. J Non-Newton Fluid Mech 1:357–370

Wein O (2004) Edge effects in rotational viscometry II. ZZ (Couette) and KK (coaxial Morse cones) sensors, no-slip pseudosimilarity. Research report ICPF no. 2004/8, Prague. Available as http://home.icpf.cas.cz/wein/Reports/AWS/(2004-8_ResRep.pdf); the related program: http://home.icpf.cas.cz/wein/Reports/AWS/(cL_nN_ZZ.exe)

Whorlow RW (1980) Rheological techniques. Ellis Horwood, Sussex, pp 136–142

Wichterle K, Wein O (1978) Rotation of non-convex bodies in plastic media. Collect Czechoslov Chem Commun 43:86–94

Williams RW (1979) Determination of viscometric data from the Brookfield R.V.T. viscometer. Rheol Acta 18:345–359. DOI 10.1007/BF01515828

Yeow YL, Ko WC, Tang PP (2000) Solving the inverse problem of Couette viscometry by Tikhonov regularization. J Rheol 44:1335–1351

Acknowledgment

This work was supported by the Grant Agency of the Czech Republic under contract nos. 104/04/0826, 104/06/P287, and 104/05/P554.

Author information

Authors and Affiliations

Corresponding author

List of symbols

List of symbols

- C :

-

total torque, Pa m3

- c L :

-

correction on end effects, c L = T / T L , see also Eq. 2

- D = d / R :

-

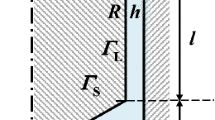

normalized distance between a rim and an axial border, Fig. 1

- E = η ∞ / η 0 :

-

viscosity ratio in the normalized Cross model, Eq. 22

- G = |∇ V| = [(∂ X V)2 + (∂ Z V)2]1/2 :

-

normalized module of velocity gradient

- h :

-

gap thickness, m

- H = h/R :

-

normalized gap thickness, Fig. 1

- K :

-

consistency coefficient for the power-law viscosity function, Pa sn

- k H :

-

estimate of the transient region length within the gap, Fig. 1

- l :

-

length of the gap between coaxial cylinders, m

- L = l / R :

-

normalized length of the gap, Fig. 1

- n :

-

global flow index for the power-law viscosity function

- n′:

-

local flow-behavior index, Eq. 4

- N :

-

intermediate flow index in the normalized Cross model, Eq. 22

- \( q = {{\mathop \gamma \limits^. }} \mathord{\left/ {\vphantom {{{\mathop \gamma \limits^. }} {{\mathop \gamma \limits^. }_{I} }}} \right. \kern-\nulldelimiterspace} {{\mathop \gamma \limits^. }_{I} } \) :

-

normalized shear rate

- Q = R shaft/R :

-

normalized shaft radius, Fig. 1

- R :

-

radius of the spindle (inner rotating cylinder), m

- Re = ΩR 2/ν :

-

Reynolds number, ν -kinematic viscosity, m2 s−1

- s = σ / σ I :

-

normalized shear stress

- s[q] = Y[q] q :

-

normalized viscosity function

- S = σ R / σ I :

-

normalized shear stress at the spindle surface for ideal Couette flow

- T = C / 2πσ I R 3 :

-

normalized torque

- T L :

-

T for ideal Couette flow, T L = S L

- T k,p :

-

contributions to T (k = C , G , A; p = srf, btm); Fig. 1, Eq. 10

- V = ω / Ω :

-

normalized velocity field

- \( W = \Omega \mathord{\left/ {\vphantom {\Omega {{\mathop {\gamma _{I} }\limits^. }}}} \right. \kern-\nulldelimiterspace} {{\mathop {\gamma _{I} }\limits^. }} \) :

-

normalized speed

- X = r/R, Z = z/R :

-

normalized meridional coordinates

- \( Y = {\eta {\mathop \gamma \limits^. }_{I} } \mathord{\left/ {\vphantom {{\eta {\mathop \gamma \limits^. }_{I} } {\sigma _{I} }}} \right. \kern-\nulldelimiterspace} {\sigma _{I} } \) :

-

normalized viscosity

- Y[q] = s[q] / q. :

-

normalized viscosity function

- α :

-

angle of the spindle cone, Fig. 1

- \( {\mathop \gamma \limits^. } \) :

-

viscometric shear rate, s−1

- \( {\mathop {\gamma _{I} }\limits^. } \) :

-

characteristic shear rate (a model parameter), s−1

- Γ :

-

spindle contour in normalized meridional plane (X, Z)

- \( \eta = \sigma \mathord{\left/ {\vphantom {\sigma {{\mathop \gamma \limits^. }}}} \right. \kern-\nulldelimiterspace} {{\mathop \gamma \limits^. }} \) :

-

viscosity, Pa s

- κ = R / (h + R):

-

ratio of radii of the inner to outer cylinder

- σ :

-

viscometric shear stress, Pa

- σ I :

-

characteristic shear stress (a model parameter), Pa

- σ R :

-

shear stress at the spindle surface for ideal Couette flow, Pa, Eq. (2)

- ω(r, z):

-

meridional field of angular speed in liquid, rad s−1

- Ω :

-

angular speed of the spindle, rad s−1

- [..]:

-

any representation of the viscosity function

- Subscripts, superscripts:

-

- L, C, G, A :

-

contours of the sensor in the (X, Y) plane, Fig. 1: ideaL gap, Cylinder faces, Gap entrance, Axis or shAft;

- srf, btm:

-

dividing the overall domain at the surface and bottom parts, Fig. 1

Rights and permissions

About this article

Cite this article

Wein, O., Vecer, M. & Havlica, J. End effects in rotational viscometry I. No-slip shear-thinning samples in the Z40 DIN sensor. Rheol Acta 46, 765–772 (2007). https://doi.org/10.1007/s00397-007-0180-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-007-0180-0