Abstract

Purpose

To enhance the water affinity of W/O emulsion-adjuvanted vaccines, we used three bioresorbable polymers named PEG-b-PLA, PEG-b-PCL, and PEG-b-PLACL as hydrophilic emulsifier to stabilize the interfaces between the oily Montanide ISA 51 adjuvant and the antigen media.

Methods

Polymers were synthesized by ring-opening polymerization of lactide and/or ε-caprolactone in the presence of monomethoxy PEG. 1H NMR and GPC data showed that obtained polymers consisted of 70 wt.% hydrophilic PEG block and 30 wt.% lipophilic PLA, PCL, PLACL block with molecular weights of 7,000.

Results

The polymer-stabilized ISA51 emulsions have high affinity to water, such that the stock of antigen-encapsulating emulsion could be re-dispersed into PBS before injection, thus yielding stable and injectable W/O/W emulsion nanoparticles. Immunogenicity studies showed that PEG-b-PLACL/ISA51/PBS-formulated ovalbumin with only 5% of ISA51 oily adjuvant could induce the same level of antibody titers as those induced by PBS/ISA51-formulated ovalbumin.

Conclusions

The novel multi-phase emulsions increase fluidity and conceptually diminish local reactions with respect to the W/O type vaccines produced from the same oil. These features are of great interest for applications in candidate vaccine delivery, especially for further optimization of alternative immunization routes, such as intramuscular, transdermal or mucosal administration.

Similar content being viewed by others

INTRODUCTION

Among the vaccine adjuvants (from the Latin adjuvare, meaning “to help”) evaluated in human trials, the emulsion-type adjuvants have the advantages of ease of manufacture and low cost (1–3). Freund’s adjuvants and Montanide ISA 51 (ISA51), containing mineral oil and lipophilic emulsifier named mannide monooleate, are defined as water-in-oil (W/O) emulsion with dispersed antigenic media and continuous oily phases (4–7). Although the mechanisms of adjuvant action are poorly understood, the W/O types of adjuvant products have been evaluated to improve the innocuity of the vaccine and to achieve long-term protective immune responses. Nevertheless, difficult injection by syringe with a needle of small diameter and local reactions at the injection site of animals that considerably restrained the potential of these emulsions for human use (5–7). To improve the injectability of such vaccines, a method consisting in re-dispersing them in an aqueous phase containing an hydrophilic emulsifier Tween®80 (polyoxyethylene sorbitan monooleate) has been described (4,6). Nevertheless, it is known that Tween®80 is a lipid dispersant in biochemistry, attacks cell walls and hence is potentially toxic (6–8). Preclinical experiences had been found that Tween®80-stabilized emulsions were generally more immunogenic than non-adjuvanted vaccines, however, also increased the reactogenicity (9,10).

In order to enlarge the number of highly safe emulsifiers in the preparation of vaccine adjuvants in specific applications, synthetic polymer can be regarded as an interesting alternative to low-molecular weight surfactants (LMWS), as the sizes and relative positions of the hydrophilic and lipophilic blocks can be easily tailored by the order of monomer addition and amounts of monomer used, thus produced a broad range of surfactant characteristics (8,11). One example is TiterMax®, wherein a squalene-based W/O emulsion is stabilized by microparticulate silica and non-ionic block copolymer polyoxyethylene-polyoxypropylene-polyoxyethylene (POE-POP-POE, known as Pluronic® or Poloxamer®) (11). Although TiterMax® elicits potent immune responses more than LMWS-emulsified formulations (11), its application in human vaccine delivery is still dubious because the stabilizers used are toxic and non-biodegradable (11,12).

Here we describe the incorporation of hydrophilic polymeric emulsifiers, namely, poly(ethylene glycol)-block-polylactide (PEG-b-PLA), poly(ethylene glycol)-block-poly(ε-caprolactone) (PEG-b-PCL), and poly(ethylene glycol)-block-poly(lactide-co-ε-caprolactone) (PEG-b-PLACL) in the antigen medium to alter the water affinity of oily ISA51-adjuvanted vaccines. These amphiphilic block copolymers were selected because of their biocompatibility and bioresorbability (13–15). Various physiochemical properties of emulsions have been characterized, namely, stability, the droplet test, particle size distribution, and in vitro release of a model protein ovalbumin (OVA). Finally, a preliminary immunogenicity evaluation of OVA after formulated with the PEG-b-PLACL-stabilized ISA51 adjuvant was determined in mice for induction of antibody responses in comparison with non-formulated OVA and conventional ISA51 oily adjuvant-formulated OVA.

MATERIALS AND METHODS

Polymer Synthesis and Characterization

Tin(II) 2-ethylhexanoate (stannous octoate, SnOct2) was purchased from Sigma (St. Louis, Missouri, USA). dl-lactide (a cyclic di-ester of lactic acid) was purchased from Aldrich (Seelze, Germany) and recrystallized from ethyl acetate. ε-Caprolactone was purchased from Aldrich. Poly(ethylene glycol) 5,000 monomethyl ether (MePEG5000) was purchased from Fluka (Buchs, Switzerland). All solvents were of analytical grade.

PEG-b-PLACL was synthesized by ring-opening polymerization of lactide and ε-caprolactone, using SnOct2 as a catalyst and MePEG5000 as an initiator (13–15). Briefly, predetermined amount of MePEG5000 (2.1 g), lactide (0.58 g), and ε-caprolactone (0.47 g) were placed in a dried round-bottomed bottle, and the appropriate amount of SnOct2 (30 mg) was added as a solution in dried toluene (10 mL). Polymerization was preceded at 140°C under reflux for 24 hr. The product was recovered by precipitation in an excessive amount of ethanol. PEG-b-PLA or PEG-b-PCL was synthesized in the same manner with MePEG/lactide or MePEG/ε-caprolactone weight ratio being 2/1.

The resulting polymers were characterized by 1H nuclear magnetic resonance (1H NMR) and gel permeation chromatography (GPC). 1H NMR spectra were recorded at room temperature with a Varian VXR 300 MHz spectrometer (Varian, Palo Alto, California, USA) using deuterated chloroform as the solvent. GPC was performed by using a setting composed of a Waters 510 HPLC pump, a Waters 410 differential refractometer, one PLgel mixed-C 5 μm 100 Å column (7.5 × 300 mm), and one PLgel 3 μm 100 Å column (7.5 × 300 mm), and, the mobile phase being tetrahydrofuran (THF) and the flow rate 0.8 mL/min. Data were expressed with respect to polystyrene standards from Polysciences.

Polymer-Stabilized Emulsions

The antigen medium was prepared with particular concentration of ovalbumin (OVA, Grade V, Sigma, St. Louis, Missouri, USA) which is diluted in the phosphate buffered saline (PBS). 120 mg of polymer, 0.8 mL of antigen medium, and 1.1 mL of ISA51 oil solution (Montanide ISA 51 F VG, SEPPIC, Paris, France) were emulsified using a Polytron® PT 3100 homogeniser (Kinematica AG, Swiss) under 6,000 rpm for 5 min. A polymer-free PBS/ISA51 emulsion composed 0.9 mL of antigen medium and 1.1 mL of ISA51 was also prepared at 8,000 rpm for 10 min. These emulsified formulations served as stocks for further physicochemical characterizations named stability, the droplet test, particle size distribution, and in vitro release.

The stability of the formulation was performed by placing each sample at 4°C and 37°C, and then noted the visual aspect at predetermined time. The droplet test was assessed with a droplet (20 μL) of emulsion into a water-containing beaker (200 mL). The particle size distribution was determined by the laser light scattering technique using a Brookhaven 90 plus particle sizer (Brookhaven Instruments Limited, New York, USA). In vitro release experiments were performed by using the inverted dialysis tube method (16). OVA-containing formulations (3 mg per 0.3 mL) were first placed in a dialysis chamber (cut-off 0.2 μm) and then the device was immersed in a 50 mL centrifuge tube containing 2 mL PBS at 37°C. At different time intervals, 100 μL of sample were aspirated from the medium outside of the chamber and then replaced with 100 μL of PBS buffer. The OVA release was regularly determined by bicinchinonic acid method (BCATM protein assay kit, Pierce, Rockford, IL, USA).

Immunization and ELISA Immunoassay

Five-week old female BALB/c mice were obtained from the National Laboratory Animal Breeding and Research Center (Taipei, Taiwan) and acclimatized for at least one week at the animal facility of National Health Research Institutes (NHRI, Miaoli, Taiwan) prior to use. All animal studies were approved by the Animal Committee of NHRI. Mice were primed subcutaneously (s.c.; 100 μL) by syringe with a needle of 27G × 1/2″ with 0.5 μg of OVA in PBS or formulated with PEG-b-PLACL/ISA51 or PBS/ISA51 and boosted with the same formulation at week 2. To increase the fluidity, the group of PEG-b-PLACL/ISA51 was investigated by re-dispersing 100 μL of stock emulsion (see “MATERIALS AND METHODS” section: Polymer-stabilized emulsions) into 900 μL of PBS before injection, resulting in PEG-b-PLACL/ISA51/PBS emulsion of only 5% oil solution.

To determine the antibody response, the mice were bled at the lateral tail vein and the collected sera were stored at -30°C until assaying. The presence of OVA-specific antibodies in the sera was determined by enzyme-linked immunosorbent assay (ELISA). In brief, 100 μL of diluted OVA (10 μg/mL) were coated into 96-well microtiter plates with 0.05 M carbonate buffer (pH 9.6) by overnight incubation at 4°C. Coated plates were washed twice with PBS containing 0.05% Tween® 20 (Sigma, St. Louis, USA) and then blocked with 5% non-fat milk in PBS at room temperature for 2 hr. Diluted sera (starting dilution 1:50, serial three-fold serum dilutions) from immunized animals were applied to wells at room temperature for 2 hr. Following the addition of HRP-conjugated goat anti-mouse IgG (ICN Cappel, Aurora, Ohio, USA), the assay was developed with substrate solution tetramethylbenzidine (TMB, Sure BlueTM, KPL, MD, USA), and the reaction was stopped in 2 N H2SO4. Plates were read at 450 nm using an ELISA plate reader (Molecular Devices, Sunnyvale, CA, USA). These titers are determined as the reciprocal of the final dilution that gave 2-fold greater absorbance than the pre-immune sera. For isotype determination, 100 μL of an appropriate dilution (1:2,000) of HRP-rabbit anti-mouse IgG1 (Zymed®, CA, USA) or HRP-rabbit anti-mouse IgG2a (Zymed®, CA, USA) was added. Statistical significance (p < 0.005) was determined by performing two-tailed Student’s t-test on log-transformed values, using Microsoft Excel.

RESULTS AND DISCUSSION

Polymer Design and Characterization

AB-type diblock copolymers consisting of a polyether block (PEG) and a polyester block (PLA, PCL or PLACL) were synthesized by ring-opening polymerization of lactide and/or ε-caprolactone in the presence of MePEG, using SnOct2 as catalyst. The molecular characteristics of the three copolymers are summarized in Table I. In this study, MePEG with molecular weight of 5,000 and an initial hydrophilic/lipophilic ratio of 2/1 were selected as a compromise between the high hydrophilicity of polymers and the bioresorbability of PEG-rich degradation products. In fact, PEG is a water-soluble polymer, particularly, low molecular weight PEG (<10,000 Da) can be excreted through kidney filtration (12). The lipophilic block is derived from U.S. Food and Drug Administration (FDA)-approved aliphatic polyesters, PLA and PCL, shows bulk degradation and further resorbs in vivo (13). PLA with variable chain stereoregularity provides a worthwhile means to adjust the rate of degradation (13,17). On the other hand, the degradation products of PCL have a relatively higher pK a than those of poly(lactide-co-glycolide) (4.8 for ε-hydroxycaproic acid, and 3.8 for lactic acid and glycolic acid at 25°C) (17), and they may provide more conservation of protein molecular integrity when being used for long-term controlled delivery of proteins. PLACL was chosen as the lipophilic block for its fast degradation characteristics (15); in addition, its amorphous nature provides good affinity between the polymer matrix and oil solutions (14,15). On the selection of catalyst, SnOct2 has been approved by the U.S. FDA for biomedical and therapeutic applications.

The molar ratio of lactyl units to caproyl units to oxyethylene or [LA]:[CL]:[OE] was determined from the integrations of the proton resonances due to PLA blocks at 5.2 ppm, to PCL blocks at 4.1 ppm, and to PEG blocks at 3.6 ppm on the 1H NMR spectra (13,14). The number average molecular weight \({\left( {\overline{{\text{M}}} {\text{n}}} \right)}\) were calculated according to the following equation:

where 44, 72 and 114 are the molecular weights of OE, LA and CL repeat units, respectively. The HLB (hydrophilic–lipophilic balance) value of non-ionic copolymers PEG-b-PLA, PEG-b-PCL, and PEG-b-PLACL is expressed according to Griffin's method (18) as follows:

where WPEG/Wcopolymer is the weight ratio of the hydrophilic portion of the main chain polymer and is obtained from \({{\overline{{\text{M}}} {\text{n}}}_{{{\text{PEG}}}} } \mathord{\left/ {\vphantom {{{\overline{{\text{M}}} {\text{n}}}_{{{\text{PEG}}}} } {{\overline{{\text{M}}} {\text{n}}}_{{{\text{copolymer}}}} }}} \right. \kern-\nulldelimiterspace} {{\overline{{\text{M}}} {\text{n}}}_{{{\text{copolymer}}}} }\). The most lipophilic has an HLB number approaching 0, and the most hydrophilic has a number of about 20. According to this equation, high HLB value (HLB PEG-b-PLA of 14.4, HLB PEG-b-PCL of 14.0, and HLB PEG-b-PLACL of 15.0) was obtained, indicating the three copolymers have high affinity to water.

The GPC traces of PEG-b-PLA, PEG-b-PCL, and PEG-b-PLACL exhibited monomodal and reflected rather narrow molecular weight distributions (Table I), indicating the absence of residual low molecular weight species. It is worth noting that the \({\overline{{\text{M}}} {\text{n}}}\) values calculated from GPC were higher than those from 1H-NMR. This finding could be assigned to changes of hydrodynamic volume of hydrophilic PEG and/or lipophilic PLA, PCL, PLACL blocks as compared with the polystyrene standards (14).

Preparation of Polymer-stabilized Emulsions

With the aim of enhancing the potency of emulsion-adjuvanted vaccines, we used hydrophilic PEG-b-PLA, PEG-b-PCL, and PEG-b-PLACL as the emulsifier to stabilize the interfaces between the ISA51 oily adjuvant and the antigen media. An aqueous phase of polymer dissolved in antigen media and an oily phase of ISA51 were emulsified using a homogenizer. The emulsifying formulation was perfectly white and isotropic from the top to the bottom.

To mimic the usual storage conditions and the post-injection stage, the stability test was investigated at 4°C and at 37°C. Upon storage at 4°C, all emulsions were stable for a few weeks without phase separation. In the case of PEG-b-PLA/ISA51 and PEG-b-PCL/ISA51, 10% of water disassociated after two weeks, but beyond this, no further water disassociation from the emulsion occurred. Isotropic emulsion could be re-formed by vortex mixing. On the other hand, approximately 10% of free oil at the surface layer disassociated from the PBS/ISA51 emulsion after one month under the same storage conditions. PEG-b-PLACL/ISA51 emulsion was stable for at least six months without phase separation. During 60 days’ monitoring at 37°C, PEG-b-PCL/ISA51 and PEG-b-PLACL/ISA51 emulsions were stable without phase separation. On the other hand, approximately 10% of free oil at the surface layer disassociated from the PBS/ISA51 emulsion after 3 days (Fig. 1a). Beyond, 30% free oil at the surface and clear layers of water (30%) at the bottom disassociated from the emulsion after one week. Phase separation happened at day 60, indicating the emulsion breaks. In the case of PEG-b-PLA/ISA51, the visual aspect changed with time was similar to the case PBS/ISA51.

a Visual aspects of the emulsions upon storage at 37°C. b Cumulative release of OVA from emulsion formulations based on bioresorbable polymer and oily adjuvant ISA51. (x symbol) Non-formulation, (open circle) PEG-b-PLA/ISA51, (open square) PEG-b-PCL/ISA51, (open upright triangle) PEG-b-PLACL/ISA51, (filled circle) PBS/ISA51. OVA-containing formulations (3 mg per 0.3 mL) were placed in a dialysis chamber in a centrifuge tube containing 2 ml PBS and stood at 37°C. OVA release was regularly monitored by BCA method (read by UV–vis instrument at 562 nm, using calibration curves obtained from standard BSA solutions). The data are presented as the mean with standard deviation of three samples.

The water affinity of the emulsions was investigated by droplet test and laser light scattering. As shown in Fig. 2a, emulsified PBS/ISA51 droplet keeps on floating on the water surface after 24 hr, the particle size was not detected by using light scattering technology. However, homogeneous particles with the size distribution of 1 μm were observed by optical microscope when re-dispersing the emulsion in ISA51 oil solution (data not shown). On the other hand, each polymer-stabilized ISA51 droplet can stand only for seconds in aqueous phase and then diffuses in the water, indicating its high affinity to water (Fig. 2b). The dynamic light scattering pattern showed PEG-b-PLA, PEG-b-PCL or PEG-b-PLACL was a suitable emulsifier for water/ISA51 interfaces, yielding narrowly distributed nanoparticles (Fig. 2b and Table I). Typically, a bimodal distribution with two different sizes was observed, the relatively large particles of 500 nm and smaller ones of 100 nm. It should be noted that this dimension is appropriate for uptake by antigen-presenting cells (APCs) to facilitate the induction of potent immune responses due to the pseudo-natural targeting of antigens (19–20). Homogenization using MePEG failed to improve the water affinity of ISA51 emulsion, the droplet rather floated on the surface than diffused in the water, this finding indicate that only PEG bearing short lipophilic units in the main chain polymer exhibits emulsifier property.

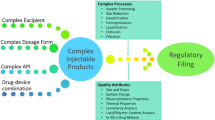

Schematic presentation of the ISA51-adjuvanted vaccine (a) before, and (b) after stabilized with bioresorbable polymers. ISA51 which contains lipophilic mannide monooleate renders W/O emulsion with high affinity for oily phase. After incorporating the hydrophilic emulsifier PEG-b-PLA, PEG-b-PCL, or PEG-b-PLACL in the antigen medium, the water affinity of oily ISA51-adjuvanted vaccine was strongly enhanced, such that the stock antigen-encapsulated emulsion could be re-dispersed into PBS, resulting homogeneous fine particles with a particle size distribution of less than 1 µm.

In addition to water affinity, PEG-b-PLA-, PEG-b-PCL-, or PEG-b-PLACL- stabilized ISA51 emulsion also provided different controlled-release profiles to hydrophilic OVA protein with respect to free OVA or PBS/ISA51-formulated OVA, as shown in Fig. 1b. Initially, a fast release was observed in the case of OVA without formulation from which more than 50% of loaded OVA was released into the outside PBS medium within the first 30 hr. The PEG-b-PLA-modified ISA51 emulsion has similar release profiles to free OVA, in which less than 30% of OVA released during the same period of time. Beyond, protein release increased continuously to reach the equilibrium concentration of inside and outside dialysis device. On the other hand, oily PBS/ISA51 emulsion presented well depot effect to OVA so that hydrophilic OVA was slowly released over 500 hr. Following the intermediate controlled-release mechanisms, the hydrophilic bioactive agents (or antigens) trapped within the PEG-b-PCL- or PEG-b-PLACL-stabilized emulsion will be released mostly by diffusion from the core oil to the surface, but also to a lesser extent by degradation mechanisms and emulsion breaks.

ISA51 oily adjuvant contains only emulsifier of low HLB value (2.6 to mannide monooleate) (6). Water affinity test and in vitro release showed that the resulting PBS/ISA51 emulsion has the continuous phase of oil and the dispersed phase being water (Fig. 2a). On the other hand, the polymer-stabilized ISA51 system composes of two surfactants, hydrophilic polymer and mannide monooleate, rendered water-in-oil-in-water (W/O/W) multi-phase emulsion (6,7,16). In this case, oil droplets dispersed into the continuous water (stabilized by polymeric emulsifier), and the core oil also entrapped aqueous phase (stabilized by mannide monooleate; Fig. 2b). The polymer-emulsified particles could serve as either carriers or vehicles to deliver antigens to APCs in a targeted and prolonged manner (19,20).

From a viewpoint of emulsion stability, vaccine emulsions meet the requirements for in vitro storage and the post-injection depot. It is generally recognized that oil droplets with small particle size and homogeneous distribution are more stable (16). However, these parameters are strongly influenced by an optimization of the emulsification process and the surfactant system. To this end, addition of excipients like glycine or glycylglycine in Montanide ISA 720, an oily adjuvant containing squalene and mannide monoolete, provided a potential way of stabilizing the emulsions both storage and post-injection (21). On the other hand, two O/W emulsion-type adjuvants that possess significant potential for the development of human vaccines are MF59 (developed from Novartis) and AS03 (developed from GlaxoSmithKline). MF59 is accomplished by using a combination of an hydrophilic Tween®80 emulsifier and a lipophilic Span®85 (sorbitan trioleate) (9), while AS03 is stabilized by Tween®80 and alpha-tocopherol (10). In the present study, PEG-b-PLA-stabilized ISA51 emulsion remained the same or reduced the stability intrinsic to ISA51 oily adjuvant. However, homogenization of PEG-b-PCL- or PEG-b-PLACL-containing aqueous solution and the mannide monooleate-contained oily phase (e.g. ISA51) provides a potential way of stabilizing the emulsified particles both at storage and at post-injection stage conditions.

Immunological Evaluation in Mice

To further evaluate the potential application of the polymer-stabilized emulsions for vaccine adjuvant, the antibody assays were performed by subcutaneous vaccination in BALB/c mice with OVA, alone or formulated with PBS/ISA51 or PEG-b-PLACL/ISA51/PBS. The latter contained only 5% of ISA51 oily adjuvant in the formulation (see “MATERIALS AND METHODS” section: Immunization and ELISA immunoassay).

As shown in Fig. 3, the serum antibody IgG, IgG1, and IgG2a titers were significantly enhanced for the groups of PBS/ISA51- and PEG-b-PLACL/ISA51/PBS- formulated OVA in comparison with the group of OVA alone (p < 0.005). Moreover, PEG-b-PLACL/ISA51/PBS-formulated OVA could induce the same level of antibody titers as those induced by PBS/ISA51-formulated OVA, i.e. PEG-b-PLACL/ISA51/PBS reserved the adjuvant effects of PBS/ISA51. We have attempted to study the effect of polymeric aqueous solutions on the enhancement of the OVA immunity. Our findings indicate that polymeric aqueous solutions have no adjuvanticity effect, the induced antigen (OVA)-specific antibodies were still in the same level as those without formulation (data not shown). We also observed PEG-b-PLACL/ISA51/PBS emulsion could be absorbed after 5 weeks’ s.c. inoculation, while PBS/ISA51 emulsion was still restrained at the injection site. Furthermore, there was no adverse side effect found in the animal experience.

Specific antibody responses in mice following immunization with OVA in different formulations. BALB/c mice were subcutaneously vaccinated twice at week 0 and 2 with dose of 0.5 μg OVA. Sera were collected from blood and the antibody titers were measured by ELISA. The data are presented as geometric mean titers with standard errors of five mice per group. *P < 0.005: comparison with non-formulated OVA group at the same time point.

Following injection, vaccine antigens may be directly taken up by APCs, bind to the surface antibody on B cells, or undergo degradation, however, only antigen taken by APCs can integrate the immune responses (2,3). The pathway taken is largely dependent on the characteristics of the antigen, but may also be influenced by the presence of adjuvants. Although emulsion-type adjuvants have been widely used for several decades, their immunogenicity-enhancing effects are still controversial due to the lack of an understanding of the complexity of colloidal dispersions, the emulsion stability of post-injection and the mechanism of the immune response what they induce (22). In the present study, the adjuvant effect of W/O emulsion (PBS/ISA51 as example) could be explained by considering the depot of emulsion to be capable of slowly releasing antigen over a long period of time (5,11). In the case of the W/O/W emulsion (PEG-b-PLACL/ISA51/PBS emulsion as example), even with only 5% of ISA51 oily adjuvant within when performing vaccination, it induced significantly higher responses than non-formulated OVA. It is probable that W/O/W not only reserved the depot effects intrinsic to ISA51 oil, but also combined the antigen presentation effects (19,20). Moreover, the ameliorated W/O/W emulsion increases injectability and conceptually diminishes local reactions with respect to the W/O type vaccines produced from the same oil.

CONCLUSION

Amphiphilic copolymers consisting of 70 wt.% hydrophilic PEG block and 30 wt.% lipophilic PLA, PCL or PLACL block were synthesized by ring-opening polymerization of lactide and/or ε-caprolactone on monomethoxy PEG5000. The resulting polymers could serve as the hydrophilic emulsifier to alter the water affinity of oily ISA51-adjuvanted vaccines, such that the stock antigen-encapsulated emulsion could be re-dispersed into PBS before injection, thus resulting stable and injectable W/O/W emulsion nanoparticles. Preliminary immunological evaluation showed that only 5% of oil within PEG-b-PLACL/ISA51/PBS formulation reserves the adjuvant effects of ISA51 oily adjuvant. These features are of great interest for further investigations of single-dose prophylactic and therapeutic vaccine development and via alternative immunization routes, such as intramuscular, transdermal or mucosal administration.

Abbreviations

- 1H NMR:

-

1H nuclear magnetic resonance

- APCs:

-

antigen-presenting cells

- BCA:

-

bicinchinonic acid

- ELISA:

-

enzyme-linked immunosorbent assay

- FDA:

-

Food and Drug Administration

- GPC:

-

gel permeation chromatography

- HLB:

-

hydrophilic-lipophilic balance

- IgG:

-

Immunoglobulin G

- ISA51:

-

Montanide ISA 51 oily adjuvant

- LMWS:

-

low-molecular weight surfactants

- MePEG5000 :

-

Poly(ethylene glycol) 5,000 monomethyl ether

- \(\overline{{\text{M}}} {\text{n}}\) :

-

number average molecular weight

- \({\overline{{\text{M}}} {\text{w}}} \mathord{\left/ {\vphantom {{\overline{{\text{M}}} {\text{w}}} {\overline{{\text{M}}} {\text{n}}}}} \right. \kern-\nulldelimiterspace} {\overline{{\text{M}}} {\text{n}}}\) :

-

molecular weight distribution

- OVA:

-

ovalbumin

- O/W:

-

oil-in-water

- PBS:

-

phosphate buffered saline

- PBS/ISA51:

-

PBS dispersed in ISA51 emulsion

- PEG-b-PCL:

-

poly(ethylene glycol)-block-poly(ε-caprolactone)

- PEG-b-PLA:

-

poly(ethylene glycol)-block-polylactide

- PEG-b-PLACL:

-

poly(ethylene glycol)-block-poly(lactide-co-ε-caprolactone)

- PEG-b-PLACL/ISA51/PBS:

-

PEG-b-PLACL-stabilized ISA51 emulsion following dispersed in PBS

- POE-POP-POE:

-

polyoxyethylene-polyoxypropylene-polyoxyethylene, s.c., subcutaneous

- SnOct2 :

-

Tin(II) 2-ethylhexanoate

- THF:

-

tetrahydrofuran

- TMB:

-

tetramethylbenzidine

- Tween®80:

-

polyoxyethylene sorbitan monooleate

- W/O:

-

water-in-oil

- W/O/W:

-

water-in-oil-in-water

References

Singh M, O'Hagan DT. Recent advances in vaccine adjuvants. Pharm Res 2002;19:715–28. doi:10.1023/A:1016104910582.

Pashine A, Valiante NM, Ulmer JB. Targeting the innate immune response with improved vaccine adjuvants. Nat Med 2005;11:S63–8. doi:10.1038/nm1210.

Singh M, O'Hagan DT. Nat Biotech 1999;17:1075–81. doi:10.1038/15058.

Vogel FR, Powell MF. A compendium of vaccine adjuvants and excipients. In: Powell MF, Newman MJ, editors. Vaccine design: the subunit and adjuvant approach. New York: Plenum; 1995. p. 141–228.

Chang JCC, Diveley JP, Savary JR, Jensen FC. Adjuvant activity of incomplete Freund’s adjuvant. Adv Drug Del Rev 1998;32:173–86. doi:10.1016/S0169–409X(98)00009-X.

Brancq B, Trouve G. US Patent 5,422,109.

Aucouturier J, Dupuis L, Deville S, Ascarateil S, Ganne V. Montanide ISA 720 and 51: a new generation of water in oil emulsions as adjuvants for human vaccines. Expert Rev Vaccines 2002;1:111–8. doi:10.1586/14760584.1.1.111.

Gaucher G, Poreba M, Ravenelle F, Leroux JC. Poly(N-vinyl-pyrrolidone)-block-poly(D,L-lactide) as polymeric emulsifier for the preparation of biodegradable nanoparticles. J Pharm Sci 2007;96:1763–75. doi:10.1002/jps.20833.

Podda A. The adjuvanted influenza vaccines with novel adjuvants: experience with MF59-adjuvanted vaccine. Vaccine 2001;19:2673–80. doi:10.1016/S0264–410X(00)00499–0.

Leroux-Roels I, Borkowski A, Vanwolleghem T, Dramé M, Clement F, Hons E, et al. Antigen sparing and cross-reactive immunity with an adjuvanted rH5N1 prototype pandemic influenza vaccine: a randomised controlled trial. Lancet 2007;370:580–9. doi:10.1016/S0140–6736(07)61297–5.

Newman MJ, Balusubramanian M, Todd CW. Development of adjuvant-active nonionic block copolymers. Adv Drug Del Rev 1998;32:199–223. doi:10.1016/S0169–409X(98)00011–8.

Jeong B, Bae YH, Lee DS, Kim SW. Biodegradable block copolymers as injectable drug-delivery systems. Nature 1997;388:860–2. doi:10.1038/42218.

Li S, Vert M. Biodegradable polymers: Polyesters. In: Mathiowitz E, editor. The encyclopedia of controlled drug delivery. New York: Wiley; 1999. p. 71–93.

Zhang Y, Wang C, Yang W, Shi B, Fu S. Tri-component diblock copolymers of poly(ethylene glycol)-poly(ε-caprolactone-co-lactide): synthesis, characterization and loading camptothecin. Colloid Polym Sci 2005;283:1246–52. doi:10.1007/s00396–005–1306–5.

Shim WS, Kim JH, Park H, Kim K, Kwon IC, Lee DS. Biodegradability and biocompatibility of a pH- and thermo-sensitive hydrogel formed from a sulfonamide-modified poly(ε-caprolactone-co-lactide)-poly(ethylene glycol)-poly(ε-caprolactone-co-lactide) block copolymer. Biomaterials 2006;27:5178–85. doi:10.1016/j.biomaterials.2006.05.038.

Aucouturier J, Dupuis L, Ganne G. Adjuvants designed for veterinary and human vaccines. Vaccine 2001;19:2666–72. doi:10.1016/S0264–410X(00)00498–9.

Youan BBC, Jackson TL, Dickens L, Hernandez C, Owusu-Ababioa G. Protein release profiles and morphology of biodegradable microcapsules containing an oily core. J Control Rel 2001;76:313–26. doi:10.1016/S0168–3659(01)00445-X.

Umbreit JN, Strominger JL. Relation of detergent HLB number to solubilization and stabilization of D-Alanine carboxypeptidase from Bacillus subtilis membranes. Proc Natl Acad Sci USA 1973;70:2997–3001. doi:10.1073/pnas.70.10.2997.

Reddy ST, Swartz MA, Hubbell JA. Targeting dendritic cells with biomaterials: developing the next generation of vaccines. Trends Immunol 2006;27:573–9. doi:10.1016/j.it.2006.10.005.

Wang C, Ge Q, Ting D, Nguyen D, Shen HR, Chen J, et al. Molecularly engineered poly(ortho ester) microspheres for enhanced delivery of DNA vaccines. Nat Mater 2004;3:190–6. doi:10.1038/nmat1075.

Miles AP, McClellan HA, Rausch KM, Zhu D, Whitmore MD, Singh S, et al. Montanide® ISA 720 vaccines: quality control of emulsions, stability of formulated antigens, and comparative immunogenicity of vaccine formulations. Vaccine 2005;23:2530–9. doi:10.1016/j.vaccine.2004.08.049.

Yang YW, Wei AC, Shen SS. The immunogenicity-enhancing effect of emulsion vaccine adjuvants is independent of the dispersion type and antigen release rate-a revisit of the role of the hydrophile–lipophile balance (HLB) value. Vaccine 2005;23:2665–75. doi:10.1016/j.vaccine.2004.09.007.

Acknowledgements

This work was supported from National Health Research Institutes by grant of VC-PP01–002. The authors are grateful to Dr. Hsing-Pang Hsieh, the Division of Biotechnology and Pharmaceutical Research of NHRI, for his help in polymer synthesis, and to Dr. Chung-Shi Yang, Center for Nanomedicine Research of NHRI for his help with the light scattering analysis. The authors are also grateful to SEPPIC (Societe d'Exploitation de Produits pour les Industries Chimiques, Paris, France) for provision of the ISA51 oil adjuvant and for helpful advice on its use.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, MH., Huang, CY., Lien, SP. et al. Development of Multi-Phase Emulsions Based on Bioresorbable Polymers and Oily Adjuvant. Pharm Res 26, 1856–1862 (2009). https://doi.org/10.1007/s11095-009-9898-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-009-9898-y